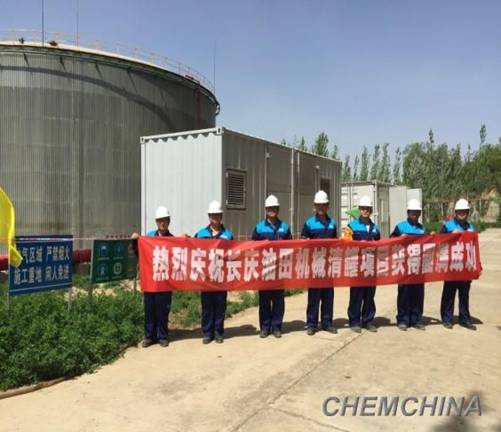

recently, beijing bluestar cleaning has successfully cleaned the qingyang 10,000m3 crude oil tank in changqing oilfield. it marked that the fully automated, visualized, manless mechanical cleaning system imported by beijing bluestar cleaning was officially put into use.

in this system, a special liquid ejection device is used to wash the tank with oil and then warm water in an enclosed, mechanical and automatic way repeatedly, and requires no one to enter the tank. in the meantime, it injects inert gas into the tank to keep the concentration of combustible gas and oxygen under control, prevent static electricity and explosion, and ensure safe operation. in this way, the tank can be cleaned rapidly and efficiently and the oil in the sediment can be recycled to the maximum extent, and the recovery rate is above 90%.

the changqing oilfield oil tank cleaning project developed the safe and scientific operation plan and guidebook and assigned dedicated staff to oversee the operation to ensure the safe and efficient cleaning of the oil tank. this operation was to clean the 4m-deep oil sludge and stains accumulated in no.4 oil tank over the years, slow down their corrosion of the oil tank, remove debris and prevent it from blocking the pipeline and the pump; later warm water was used to wash the tank to completely remove inflammable materials such as oil stains and meet the inspection standard for hot work.