on april 8, elkem spark silicones had put into production its first 10mt/a kn95 silicone mask production line, which will produce 900,000 silicone masks monthly to aid the front line of global epidemic prevention. this production line has just spent 35 days to complete the whole process, ranging from the project approval, design, and market positioning to commissioning test run; such an exciting "china speed" has embodied the great burst of energy in concerted efforts of elkem spark silicones to fight the epidemic under the guidance of industry leading and social responsibility as a central enterprise, and best manifested the comprehensive strength of the enterprise in all dimensions and its abilities of control, coordination and innovation to the industry chain.

facing the shortage of medical epidemic prevention supplies, elkem spark silicones has turned the crisis into an opportunity, and innovated to provide a new generation of kn95 silicone masks with the latest technology and at the fastest speed. taking advantages of corporate raw materials and the group's internal resources, this production line was built by utilizing the used equipment and renovating the existing silicones no. 4 plant warehouse, totaling the auxiliary production lines of solid molding press, liquid molding press and injection molding machine.

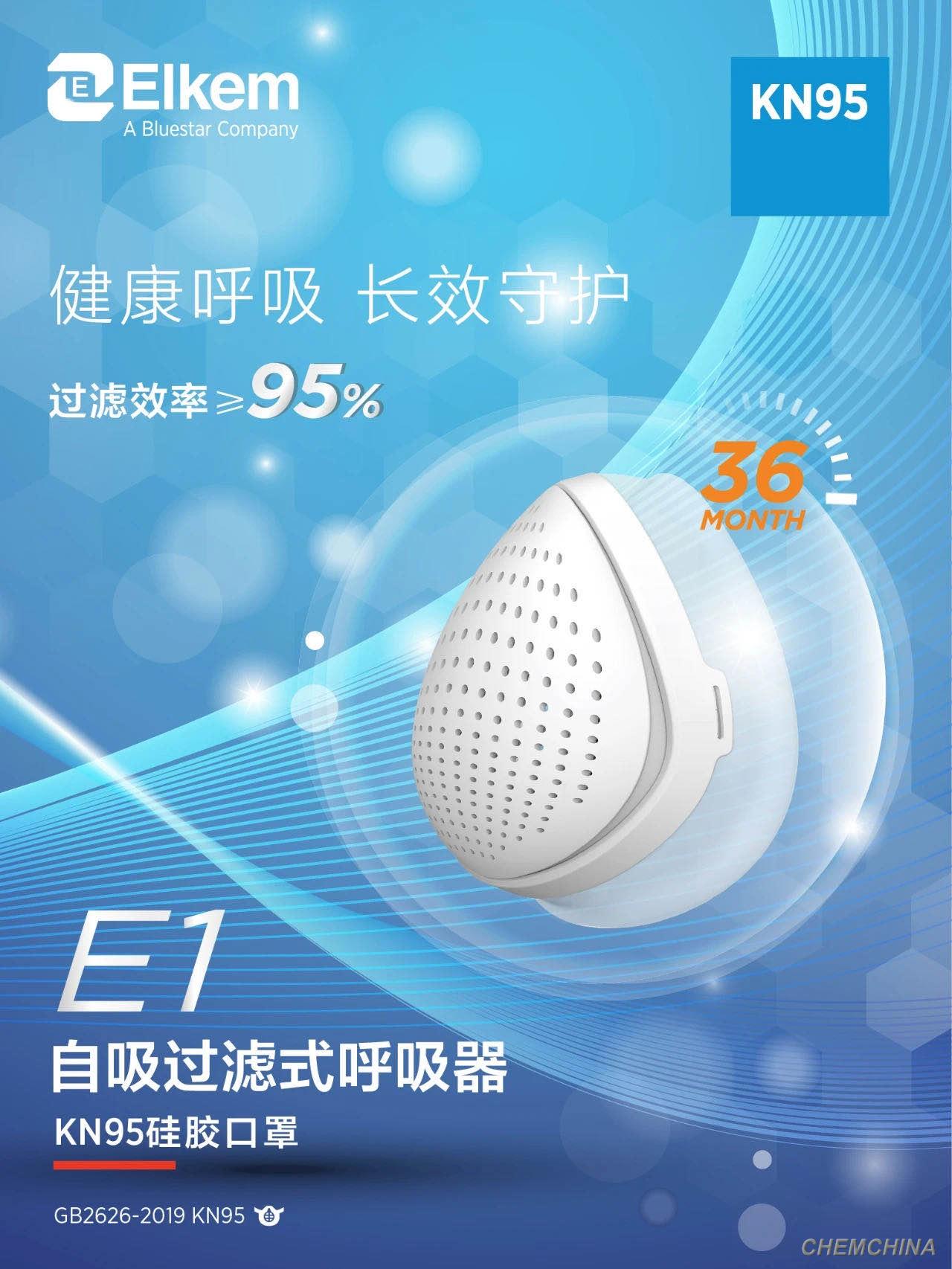

the silicone mask, also known as the non-powered air-purifying respirator, adopts the 5-layer kn95 filter design, which can effectively filter bacteria, droplets, dust and other substances in the air, with a filtering efficiency of more than 95%. elkem spark silicones takes bluesiltmlsr 8600 series of products of self-produced food grade liquid silicone rubber as the raw material of such mask, so that wearing them for a long time is less likely to cause allergic skin reactions. the good sealing performance is more closely fitting to the face shape, the excellent flexibility and adjustable stretching silicone ear rope will not pull the wearer's ear at all. the product is resistant to high temperature and will not be boiled out of shape. the mask may be reused by simply changing the filter.

next, based on market research, elkem spark silicones will successively launch the specially designed silicone masks for europeans and children, continuing to provide solid material support for the global fighting against the epidemic.